Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms, where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

In today’s fast-evolving industrial landscape, seamless steel pipe plays a vital role in construction, energy, oil and gas, automotive, and machinery. Unlike welded pipes, seamless steel pipes are produced without seams or joints, providing superior strength, uniformity, and resistance to pressure. According to industry data from the International Steel Association, the demand for seamless steel pipe is projected to grow steadily due to its use in high-pressure and high-temperature environments.

This article explores its characteristics, applications, advantages, and how choosing the right supplier, like Liaocheng Jiuyang Steel Pipe, can impact your project success.

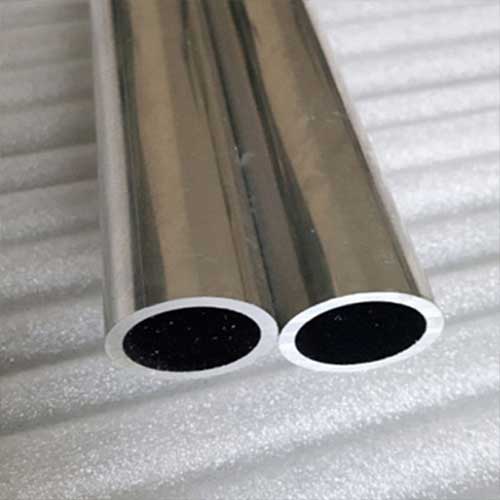

What is a Seamless Steel Pipe?

Seamless steel pipe is manufactured through a solid billet that is pierced to create a hollow tube, followed by elongation and sizing to reach the required dimensions. This process eliminates weld seams, ensuring uniform strength and reducing the risk of failure under stress. Seamless steel pipe is especially popular in critical sectors such as oil drilling, energy transport, chemical processing, and automotive manufacturing.

Advantages of Seamless Steel Pipe Over Welded Pipe

When comparing seamless and welded pipes, seamless steel pipe holds distinct advantages in strength, durability, and performance.

| Feature | Seamless Steel Pipe | Welded Steel Pipe |

|---|---|---|

| Strength | Higher, uniform across the pipe | Slightly weaker at weld seams |

| Pressure Resistance | Excellent for high-pressure applications | Limited by the weld seam strength |

| Temperature Resistance | Superior in extreme heat environments | Less efficient in extreme temperatures |

| Production Cost | Higher, due to complex manufacturing | Lower, easier production process |

| Applications | Oil, gas, chemical, automotive, aerospace | Water transport, structural uses |

This difference explains why seamless steel pipe is the first choice for industries where safety and reliability cannot be compromised.

Applications of Seamless Steel Pipe in Oil and Gas

Seamless steel pipe is indispensable in oil and gas drilling. It withstands high internal pressures, extreme temperatures, and corrosive environments. According to data published by the Oil & Gas Journal, more than 70% of drilling casing materials worldwide are seamless steel pipes because of their superior resistance to cracking under stress.

Seamless Steel Pipe in Construction and Infrastructure

Beyond energy, seamless steel pipe is widely used in modern construction. From skyscrapers to bridges, these pipes ensure structural integrity due to their high load-bearing capacity. They are also used in pipelines for water and gas distribution, where long-term reliability is essential.

Seamless Steel Pipe for Automotive and Mechanical Engineering

Automotive and machinery industries rely on seamless steel pipe for critical parts such as drive shafts, cylinders, and bearings. The precision dimensions and excellent mechanical properties of seamless steel pipe ensure efficiency and longevity in moving components.

Corrosion Resistance and Surface Treatments

While seamless steel pipe already offers superior strength, additional coatings such as galvanization, epoxy, or painting further improve corrosion resistance. This makes seamless steel pipe an excellent choice for offshore oil rigs, marine structures, and environments with high humidity or chemical exposure.

Quality Standards for Seamless Steel Pipe

Manufacturers of seamless steel pipe must adhere to strict international standards such as ASTM, API, and EN. These standards specify chemical composition, tensile strength, hardness, and dimensional tolerances. Liaocheng Jiuyang Steel Pipe ensures compliance with these standards, providing products that meet or exceed industry benchmarks.

How to Select the Right Seamless Steel Pipe Supplier

When sourcing seamless steel pipe, choosing the right supplier is as important as selecting the right material. Consider these factors:

- Quality Certifications: Ensure compliance with global standards.

- Production Capacity: Reliable suppliers can meet bulk demands on time.

- Technical Support: Suppliers should provide guidance on selecting the right grade and size.

- After-Sales Service: Long-term support guarantees peace of mind.

Liaocheng Jiuyang Steel Pipe is recognized for its commitment to quality, innovation, and customer satisfaction, making it a trusted partner in the global steel market.

Future Trends in Seamless Steel Pipe Industry

The seamless steel pipe industry is moving towards sustainability and innovation. With increasing demand for energy and infrastructure, manufacturers are developing new alloys with improved corrosion resistance, reducing production emissions, and investing in digitalized manufacturing processes to enhance precision.

Conclusion

Seamless steel pipe continues to be the backbone of industries that demand durability, precision, and reliability. From oil and gas to automotive and construction, its superior performance makes it irreplaceable in critical applications.

Liaocheng Jiuyang Steel Pipe provides seamless steel pipe solutions that combine advanced technology with strict quality control, ensuring that every product meets the highest industry standards. If you are looking for seamless steel pipe that delivers unmatched strength and value, Liaocheng Jiuyang Steel Pipe is your trusted partner.

FAQ

What is the difference between seamless steel pipe and welded pipe?

Seamless steel pipe has no weld seam, offering higher strength and uniformity, while welded pipes may have weak points at the weld.

What industries use seamless steel pipe the most?

Oil and gas, automotive, construction, aerospace, and chemical processing industries are the largest consumers of seamless steel pipe.

How is seamless steel pipe manufactured?

It is made by piercing a solid billet to form a hollow tube, followed by rolling and sizing to achieve the desired dimensions.

Does seamless steel pipe resist corrosion?

Yes, seamless steel pipe resists corrosion, and additional coatings can improve durability in harsh environments.

Why choose Liaocheng Jiuyang Steel Pipe as a supplier?

Because of strict quality control, compliance with international standards, strong production capacity, and excellent customer service.