Table of Contents

What is an Aluminum Coil?

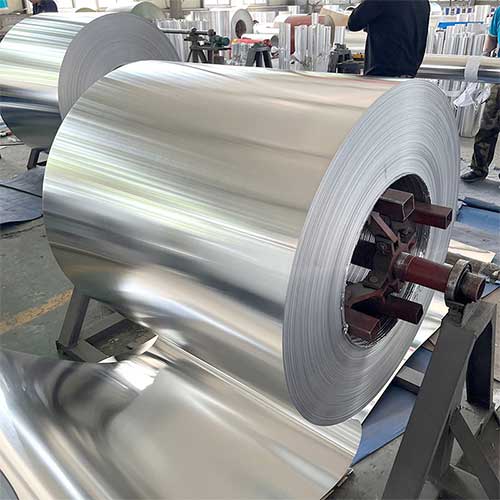

An aluminum coil is a rolled product made from aluminum sheets, which are processed through rolling mills to produce a thin, continuous coil. These coils are often used as raw materials in a wide range of industries due to their numerous benefits, including their strength-to-weight ratio, resistance to corrosion, and ease of manipulation.

Aluminum coils are available in various grades, thicknesses, and finishes, making them highly versatile for different applications. Whether you’re in the construction, automotive, or packaging industry, aluminum coils can be customized to meet specific project requirements.

Key Benefits of Using Aluminum Coil in Manufacturing

1. Lightweight yet Strong

One of the primary reasons why aluminum coils are favored in manufacturing is their lightweight nature. Compared to other materials like steel, aluminum offers a high strength-to-weight ratio, which is crucial in industries like automotive and aerospace, where weight reduction is essential for improving fuel efficiency and performance. Despite being lighter, aluminum coils provide excellent strength, making them ideal for structural applications.

2. Exceptional Corrosion Resistance

Aluminum’s natural ability to resist rust and corrosion makes aluminum coils perfect for use in environments where exposure to the elements is inevitable. This feature is particularly advantageous in industries like construction, where materials must endure extreme weather conditions without degrading. The aluminum oxide layer that forms naturally on the surface of the coil helps to protect it from corrosion, ensuring long-lasting durability.

3. Sustainable and Recyclable

Aluminum coils are not only durable but also highly sustainable. Aluminum is one of the most recyclable materials on the planet, and the recycling process uses only a fraction of the energy required to create new aluminum. The recycling of aluminum coils significantly reduces environmental impact, making it an excellent choice for businesses aiming to adopt more eco-friendly practices.

Common Applications of Aluminum Coil in Various Industries

1. Aluminum Coils in the Construction Industry

Aluminum coils are widely used in construction applications, such as for roofing, wall panels, and facades. The lightweight nature of this material makes it easy to install, while its corrosion resistance ensures its longevity. In modern architecture, aluminum coil is often chosen for its aesthetic appeal, as it can be coated in various colors, providing both functionality and style.

Example Uses:

- Roofing materials

- Exterior panels for buildings

- Window frames and trim

2. Aluminum Coil in the Automotive Industry

In the automotive industry, aluminum coils are increasingly being used for the manufacturing of lightweight components. This helps reduce the overall weight of vehicles, which in turn improves fuel efficiency. Aluminum is commonly used in car parts such as doors, hoods, and heat exchangers.

Benefits for the Automotive Industry:

- Improved fuel efficiency due to lighter weight

- Durability and safety due to aluminum’s strength

- Better thermal conductivity in heat exchangers

3. Aluminum Coil in Packaging

Aluminum coils are also crucial in the packaging industry, particularly in the production of food and beverage containers. Aluminum is an excellent barrier to light, oxygen, and moisture, making it ideal for packaging products that need to stay fresh longer.

Applications in Packaging:

- Beverage cans

- Food containers and packaging

- Foil wraps

How to Choose the Right Aluminum Coil for Your Project

Choosing the right aluminum coil for your project can be a complex decision, as it depends on various factors such as thickness, grade, and surface finish. Here are some key considerations to help guide your choice:

1. Determine the Right Grade of Aluminum

Aluminum coils come in different grades, each offering distinct benefits. The two most common aluminum grades used in coil production are the 1000 and 3000 series. The 1000 series is highly pure aluminum, offering excellent corrosion resistance, while the 3000 series offers better strength and formability, making it ideal for more demanding applications.

2. Consider the Thickness and Width

The thickness and width of the aluminum coil will depend on the specific requirements of your project. If you’re using the coil for structural components, a thicker, wider coil may be required. However, for packaging or decorative purposes, a thinner, narrower coil may suffice.

3. Surface Finish

The surface finish of the aluminum coil is another important factor to consider. Some industries require a matte finish for aesthetic reasons, while others may need a smooth finish for applications requiring minimal friction. Be sure to select a finish that aligns with the functional and aesthetic requirements of your project.

Table: Comparison of Aluminum Coil Grades

| Grade | Characteristics | Common Applications | Strength |

|---|---|---|---|

| 1000 Series | Pure aluminum with excellent corrosion resistance | Roofing, signage, decorative panels | Moderate |

| 3000 Series | Contains manganese for improved strength | Automotive parts, heat exchangers, packaging | High |

| 5000 Series | Contains magnesium for high strength and corrosion resistance | Marine, outdoor applications, tanks | Very High |

Conclusion

In conclusion, aluminum coils are a versatile, durable, and sustainable material that plays a significant role in industries such as construction, automotive, and packaging. Their lightweight nature, corrosion resistance, and recyclability make them an ideal choice for businesses looking to enhance performance while reducing environmental impact. By understanding the various applications and benefits of aluminum coils, you can make a more informed decision when selecting materials for your next project.

FAQ

What are aluminum coils used for?

Aluminum coils are used in various industries such as construction (roofing, facades), automotive (lightweight components), and packaging (cans, containers). Their applications span a wide range of uses due to their lightweight, corrosion-resistant, and durable properties.

How do I choose the right aluminum coil for my project?

To choose the right aluminum coil, consider factors such as grade, thickness, width, and surface finish. The project’s requirements, such as strength, durability, and aesthetic preferences, will guide the decision.

Are aluminum coils recyclable?

Yes, aluminum coils are highly recyclable. The recycling process uses only a fraction of the energy required to produce new aluminum, making it an environmentally friendly choice.

What are the advantages of aluminum coils over steel coils?

Aluminum coils are lighter, more resistant to corrosion, and have better thermal conductivity compared to steel coils. These qualities make aluminum a preferred material in many applications, including automotive and construction.

How durable are aluminum coils?

Aluminum coils are incredibly durable, especially when treated for corrosion resistance. They can withstand harsh environmental conditions, making them ideal for outdoor and industrial applications.