Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Why Choose Aluminum Coil Over Steel Coil? Key Advantages Explained

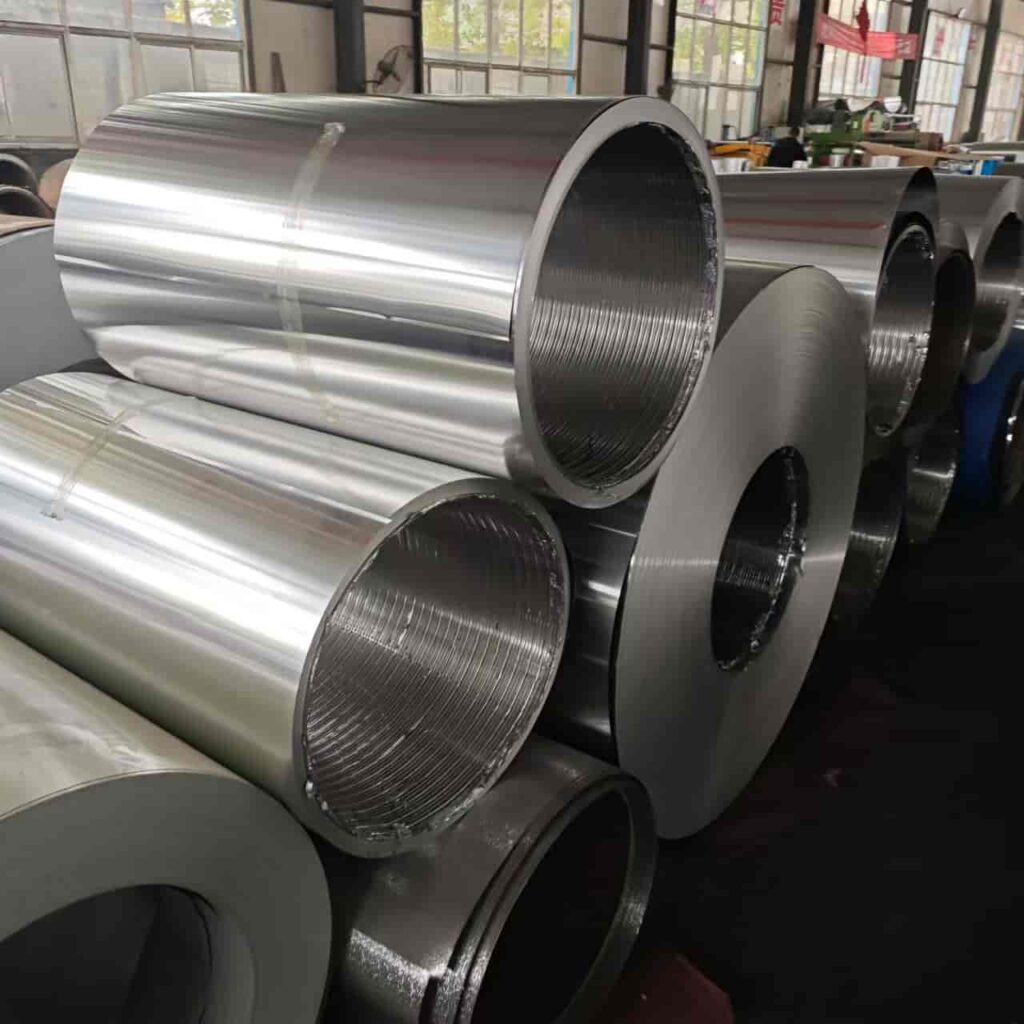

There are several compelling reasons why aluminum coil is chosen over steel coil for various applications. Aluminum’s natural properties—such as being lightweight, resistant to corrosion, and sustainable—make it an ideal material for many industries, including automotive, construction, and packaging. Let’s explore the primary benefits of aluminum coil in comparison to steel coil.

1. Aluminum Coil vs. Steel Coil: Which Material is Lighter and Stronger?

One of the most significant advantages of aluminum coil over steel coil is its weight. Aluminum is much lighter than steel, making it a top choice for industries where weight reduction is critical. In the automotive industry, for example, lighter vehicles help improve fuel efficiency and reduce overall energy consumption. Aluminum’s strength-to-weight ratio is exceptional, which makes it suitable for a wide range of applications without compromising on strength.

Weight Comparison:

- Aluminum Coil: 2.7 g/cm³

- Steel Coil: 7.85 g/cm³

Aluminum’s lighter weight makes it easier to handle during manufacturing and reduces transportation costs. The reduced weight is particularly valuable in industries where high strength is still necessary but minimizing weight is a priority, such as in the aerospace or automotive sectors.

2. Corrosion Resistance: How Aluminum Coil Outperforms Steel Coil

Corrosion resistance is one of aluminum’s most significant advantages. Aluminum coils naturally form a protective oxide layer when exposed to air, making them resistant to rust and corrosion. In comparison, steel requires coatings like galvanization to prevent rust, and even then, steel can still corrode if the coating is damaged.

Corrosion Resistance Summary:

- Aluminum Coil: Naturally corrosion-resistant, requiring no additional coatings.

- Steel Coil: Requires anti-corrosion treatments and still prone to rust.

Aluminum is ideal for applications exposed to harsh weather conditions, such as in construction or outdoor signage. Its corrosion resistance ensures long-term durability and reduces maintenance costs, making it a more cost-effective option in the long run.

3. Sustainability: Is Aluminum Coil More Environmentally Friendly Than Steel Coil?

Sustainability is an increasingly important factor for businesses looking to reduce their environmental impact. Aluminum coils are highly sustainable due to their recyclability. Aluminum is 100% recyclable, and recycling aluminum requires only 5% of the energy used to create new aluminum from raw materials. This makes aluminum an environmentally friendly material choice compared to steel, which also can be recycled but demands more energy during the process.

Aluminum’s low energy consumption during recycling and its high recyclability make it a more sustainable option, especially for companies focusing on reducing their carbon footprint. By choosing aluminum, you can contribute to a circular economy and lower the environmental impact of your products.

4. Durability of Aluminum Coil vs. Steel Coil: Which Lasts Longer?

While steel is known for its strength, aluminum coil offers superior longevity in many applications, particularly those exposed to the elements. Aluminum’s natural resistance to corrosion, oxidation, and degradation ensures it has a longer lifespan compared to steel in certain conditions. Steel, on the other hand, can suffer from rust and may require more frequent maintenance, especially when exposed to moisture and salt.

Durability Comparison:

- Aluminum Coil: Resistant to corrosion, UV rays, and harsh weather conditions.

- Steel Coil: Needs coatings to protect against corrosion; may degrade over time.

In construction, marine, and automotive industries, where long-term durability is essential, aluminum offers an advantage in maintaining performance over time. This makes aluminum a preferred choice for applications that demand longevity.

5. Applications of Aluminum Coil vs. Steel Coil: Which Works Best for Your Industry?

Both aluminum coils and steel coils are versatile materials used in various industries, but their applications often differ based on material properties. Here’s a breakdown of how each material performs in different sectors:

Industry Applications:

- Construction: Aluminum is used for roofing, facades, and window frames because of its lightweight and corrosion-resistant properties. Steel is often used in structural framing and reinforcements.

- Automotive: Aluminum is increasingly used in automotive parts to reduce vehicle weight and improve fuel efficiency. Steel is still widely used for car chassis and other heavy-duty components.

- Packaging: Aluminum is used for food and beverage cans, as well as foil wraps, thanks to its excellent barrier properties. Steel is not commonly used in packaging due to its weight and susceptibility to corrosion.

Each material serves specific needs based on its physical properties. For example, aluminum is favored for lightweight applications, while steel is used for structural integrity in heavy-duty environments.

6. Weight Differences: How Aluminum Coil Reduces Project Weight

The weight of materials directly affects the overall weight of finished products. In industries such as automotive and aerospace, reducing weight is a significant factor in improving performance. Aluminum coils are much lighter than steel coils, helping reduce the total weight of vehicles, airplanes, and other products without sacrificing strength.

Example:

- Reducing a car’s weight by 10% using aluminum can improve fuel efficiency by up to 6-8%.

The weight reduction in vehicles, for example, can result in better fuel economy, reduced emissions, and enhanced performance. These benefits are especially valuable for companies that prioritize efficiency and sustainability.

7. How Aluminum Coil Offers Better Formability Than Steel Coil

Aluminum coils offer superior formability compared to steel coils. Aluminum is more malleable, allowing manufacturers to shape it into intricate designs with less effort. This property is especially useful in industries where detailed, complex shapes are required, such as in automotive body panels or decorative architectural features.

Formability Comparison:

- Aluminum Coil: Easier to form and shape, offering greater flexibility in design.

- Steel Coil: More rigid and harder to shape without requiring significant energy and resources.

Aluminum’s better formability leads to more design options and ease of production, making it a more adaptable choice for projects requiring high precision and customization.

8. Cost Comparison: Is Aluminum Coil More Affordable Than Steel Coil?

While aluminum coils are typically more expensive than steel coils upfront, their overall cost-effectiveness can be higher in the long term. Aluminum’s durability, corrosion resistance, and lightweight properties lead to lower maintenance and operational costs. On the other hand, steel coils, while more affordable initially, can incur higher maintenance costs due to their susceptibility to rust and corrosion.

Cost Summary:

- Aluminum Coil: Higher initial cost but lower long-term maintenance and energy costs.

- Steel Coil: Lower upfront cost, but higher long-term maintenance costs.

Choosing aluminum can provide savings over time, especially when you factor in reduced repair and maintenance expenses. For projects that require long-term performance and minimal upkeep, aluminum may be the better investment.

Table: Aluminum Coil vs. Steel Coil Comparison

| Feature | Aluminum Coil | Steel Coil |

|---|---|---|

| Weight | 2.7 g/cm³ (Lightweight) | 7.85 g/cm³ (Heavy) |

| Corrosion Resistance | Naturally resistant | Requires anti-corrosion coatings |

| Recyclability | 100% recyclable, low energy use | Recyclable, but more energy needed |

| Durability | High (especially outdoors) | Medium (requires maintenance) |

| Cost | Higher initial cost | Lower upfront cost |

| Formability | Better (easier to shape) | Less flexible |

Conclusion

The advantages of aluminum coil compared to steel coil are clear when examining factors like weight, corrosion resistance, sustainability, and long-term cost savings. Whether you’re in the construction, automotive, or packaging industry, aluminum coils offer significant benefits that steel coils often cannot match. Their lightweight nature, durability, and eco-friendliness make them the material of choice for businesses looking to improve performance while reducing environmental impact.

If you’re considering aluminum coils for your next project, Jiuyang Steel is your trusted partner. We offer high-quality aluminum coils that meet the needs of a wide range of industries. Contact Jiuyang Steel today to learn more about how our products can support your project’s performance, sustainability, and cost efficiency.

FAQ

Why is aluminum coil preferred over steel coil?

Aluminum coils are lighter, more corrosion-resistant, and offer better formability, making them ideal for applications in automotive, construction, and packaging.

Is aluminum coil more expensive than steel coil?

Aluminum coils have a higher upfront cost, but their durability and long-term benefits, such as lower maintenance costs, make them more cost-effective in the long run.

What are the most common applications for aluminum coils?

Aluminum coils are widely used in industries like construction (roofing, facades), automotive (lightweight body parts), and packaging (cans, food containers).

How does aluminum coil improve energy efficiency?

By reducing the weight of vehicles and aircraft, aluminum coils help improve fuel efficiency, reducing energy consumption and emissions.

Is aluminum coil a sustainable material?

Yes, aluminum coils are 100% recyclable, and recycling aluminum uses significantly less energy compared to producing new aluminum, making it an environmentally friendly material.