Galvanized Pipe

Galvanized Pipe

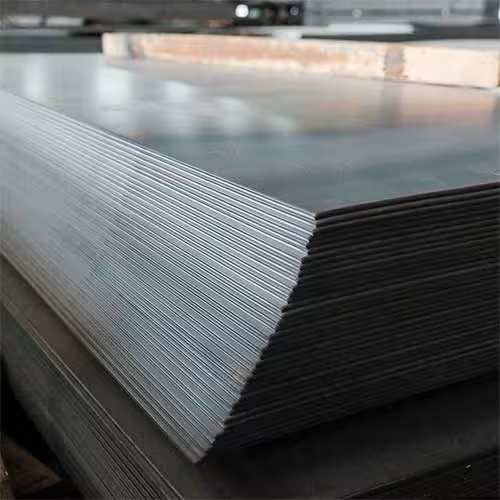

Galvanized pipe refers to a steel pipe with a layer of zinc on the surface. It can be divided into hot-dip galvanized steel pipe and cold-dip galvanized steel pipe.

Galvanized Pipe

Hot-dip galvanized steel pipe

- Production process: The steel pipe is first pickled to remove surface iron oxide, then cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixture thereof, and then sent to a hot-dip plating tank. The molten metal reacts with the iron matrix to produce an alloy layer, which tightly combines the matrix and the coating.

- Advantages: uniform coating, strong adhesion, long service life, and strong corrosion resistance.

- Application: Widely used in construction, machinery, coal mines, chemical industry, electric power, railway vehicles, automobile industry, highways, bridges, containers, sports facilities, agricultural machinery, petroleum machinery, prospecting machinery and other manufacturing industries. Such as roofs, walls, and ventilation ducts in the construction field; fire ducts in the fire protection field.

Cold-dip galvanized steel pipe

- Production process: Electro-galvanizing, zinc ions are deposited on the surface of the steel pipe through electrolysis.

Disadvantages: The amount of galvanizing is small, only 10-50g/m², and the corrosion resistance is much worse than that of hot-dip galvanized pipes. The zinc layer is independently layered with the steel pipe matrix. The zinc layer is thin and easy to fall off. - Application status: Due to poor corrosion resistance, it has been banned in most countries. The Ministry of Construction has also officially phased out cold-galvanized pipes and is not allowed to use them as water and gas pipes. In new residential buildings, it is prohibited to use cold-dip galvanized steel pipes as water supply pipes.

- When selecting galvanized pipes, factors such as the use environment and corrosion resistance requirements need to be considered. If used in humid or highly corrosive environments, hot-dip galvanized steel pipes are more suitable; when corrosion resistance is not high and cost is important, other pipes can be considered or cold-dip galvanized steel pipes can be selected under appropriate circumstances (but pay attention to its use limit). At the same time, attention should be paid to product quality, and indicators such as the thickness and uniformity of the galvanized layer and the mechanical properties of the steel pipe should be checked.

Reviews

There are no reviews yet.