Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

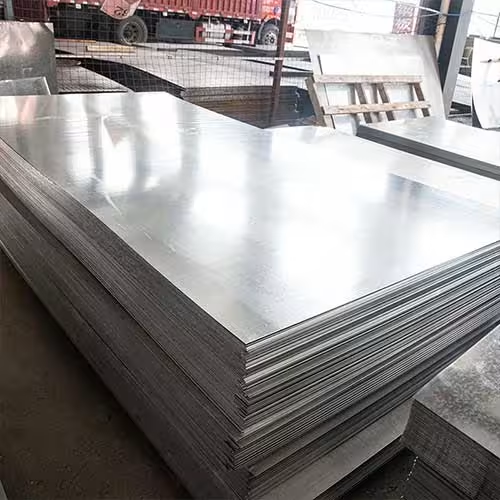

When you’re selecting materials for construction, fabrication, roofing, or storage applications, understanding the value of galvanized steel sheets is essential. These sheets combine strength, durability, and corrosion resistance thanks to a zinc coating that protects the core steel.

In this guide, you’ll discover what makes galvanized steel sheets unique, how they’re manufactured, which long-tail applications they support—including coil-to-sheet production, corrugated panels, and cladding—and how to choose the right grade for your needs.

What Are Galvanized Steel Sheets?

The Manufacturing and Zinc Coating Process

Galvanized steel sheets begin as cold-rolled or hot-rolled steel that undergoes surface cleaning before being dipped in molten zinc. This galvanic layer protects from rust, extends service life, and improves resistance to abrasion and weathering. According to industry alloy coatings guidelines, properly galvanized coatings can double the life of exterior steel surfaces in urban and industrial environments.

Common Gauges, Thicknesses, and Coating Weights

These sheets are available in gauges from 20 g (~0.9 mm) up to 10 g (~3 mm), with coating weights typically ranging from G30 to G90 (grams of zinc per square meter). Thicker gauge sheets and heavier coatings provide increased protection and structural stiffness—ideal for industrial paneling or metal roofing.

Key Benefits of Galvanized Steel Sheets

Corrosion Resistance and Longevity

The zinc layer acts sacrificially, preventing oxidation of the steel. In many test environments, galvanized steel sheets exhibit minimal rust after 500 hours of salt spray exposure, outperforming plain steel by a factor of 10.

Cost-Effectiveness Over Time

Compared to stainless steel or painted finishes, galvanized sheets deliver budget-friendly durability. One industry study showed a return on investment within five years for roofing or structural cladding when using galvanized options.

Structural Strength and Formability

They balance stiffness for load-bearing panels with ductility for bending or roll forming. That’s why galvanized steel sheets are preferred for applications like rainwater gutters, industrial shelving, and corrugated roofing.

Versatility Across Use Cases

These sheets support coil-to-sheet conversions, corrugated roof panel creation, metal siding, perforated panel systems, industrial kitchen cladding, and even structural composite wall systems. Their adaptability and consistency make them go-to materials across construction and fabrication sectors.

How to Choose the Right Galvanized Steel Sheets for Your Project

Select by Coating Grade and Thickness

Choose heavier coatings (e.g. G60–G90) for exposure to moisture or corrosive environments. For indoor or protected use, lighter coatings (G30–G40) offer enough protection with less cost and weight.

Pick the Appropriate Sheet Gauge or Mill Thickness

Thin sheet gauges (20–24 g) are ideal for bending and cladding; heavier sheets (14–10 g) offer rigidity for structural or decking applications. Rolling or forming operations benefit from a consistent steel thickness.

Consider Post-Galvanizing Treatments

Passivation and chromate treatments improve adhesion of paints or powder coatings. In case of customization—e.g. powder-coated profile sheets—surface treatments ensure uniform finish and adhesion.

Inspect for Surface Quality and Peel Strength

Look for smooth, spangle-free finishes, consistent zinc layer, and peel ratings above 25 N/mm per relevant standards. Good surface quality prevents early deterioration or visual defects.

Essential Applications and Long-Tail Use Cases

Roofing & Corrugated Panel Applications

Galvanized corrugated roof sheets provide durable covering for warehouses, agricultural sheds, or carports. The ridge spacing and profile vary—but the underlying galvanized sheet ensures long-term weather resistance and load capacity.

Structural Decking & Composite Floor Systems

These sheets serve as a decking layer over concrete slabs or steel framing. Their high stiffness and corrosion resistance eliminate the need for additional rust-resistant coatings in many installations.

Industrial Kitchen and Food Prep Surfaces

Stainless alternatives can be pricey—galvanized steel sheets offer a hygienic and rust-resistant substrate for food prep backsplashes, under-counter panels, and equipment housing. Long-tail keywords include “galvanized food service wall panel sheet.”

Electrical Enclosures and Control Panels

When making control cabinets or electrical housings, these sheets offer protective strength and grounding surface. They can be bent into boxes or formed with knockouts while maintaining structural integrity.

Perforated and Ventilation Panels

Perforated galvanized sheets are used for HVAC grilles, equipment guards, and facade elements—keywords like “galvanized perforated sheet metal panel” align with purchase and design searches.

Practical Comparison Table

| Application Area | Recommended Gauge | Coating Grade | Why It Works |

|---|---|---|---|

| Roofing / Corrugated zinc | 20–18 g | G60–G90 | Lightweight, corrosion-resistant, rigid |

| Industrial deck flooring | 16–14 g | G90 | High strength, durable under load |

| Kitchen backing panels | 24–22 g | G30–G60 | Formable, easy to clean, hygienic surface |

| Control box housing | 22–20 g | G40–G60 | Good formability, surface conductivity |

| HVAC perforated panels | 24–20 g | G60 | Sturdy, corrosion-resistant, ventilated |

Maintenance and Longevity Best Practices

Routine Visual Inspection

Check galvanized surfaces for white rust or localized pitting. After installation, inspect seams or cut edges where coating may be compromised.

Repair Techniques for Damaged Areas

If zinc coating is scratched or cut, apply cold galvanizing compound or zinc-rich paint to exposed steel to restore protection.

Long-Term Care and Cleaning

Keep surfaces free of debris and chemical exposure. Periodically rinse rooftop panels or siding with water to remove dust or airborne chloride buildup.

End-of-Life and Recyclability

Galvanized steel sheets are fully recyclable—scrap materials can be recovered as zinc-coated scrap steel, reducing environmental impact. Most recycling centers separate by zinc content.

Conclusion

By choosing the appropriate gauge, coating grade, and post-treatment options, galvanized steel sheets give you a versatile solution for roofing, structural panels, kitchen environments, cabinetry, and industrial enclosures. Armed with this guide, you’re equipped to reduce maintenance, resist corrosion, and design confidently.

If you’re ready to specify the best galvanized steel sheets for your next project or want tailored recommendations on grade, thickness, or forming techniques, our team is here to assist. Contact us today for expert sourcing and support that ensures seamless performance and reliability.

FAQ

Are galvanized steel sheets suitable for outdoor roofing?

Yes—they are designed for exposure, especially with G60 or higher coating grades, offering service lifetimes of 20+ years in moderate environments.

Can galvanized sheets be painted or powder coated?

Absolutely—surface treatments improve adhesion, and sanding or scuffing before painting is recommended. Proper template matching ensures paint bonds uniformly.

How do I avoid weld burn and coating loss?

Use proper welding techniques—MIG or TIG with zinc filler rods—and apply touch-up galvanizing after welding. Grind and seal edges to prevent corrosion.

Is galvanized sheet heat-resistant for kitchen environments?

Yes—zinc coating withstands moderate heat, and the underlying steel maintains structural strength at elevated kitchen temperatures. Just avoid direct flame contact.

Are these sheets better than stainless steel for budget-sensitive projects?

For many applications, yes—galvanized steel sheets offer corrosion protection at a fraction of the cost of stainless steel, with the tradeoff of lessalkali or acid resilience.