Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

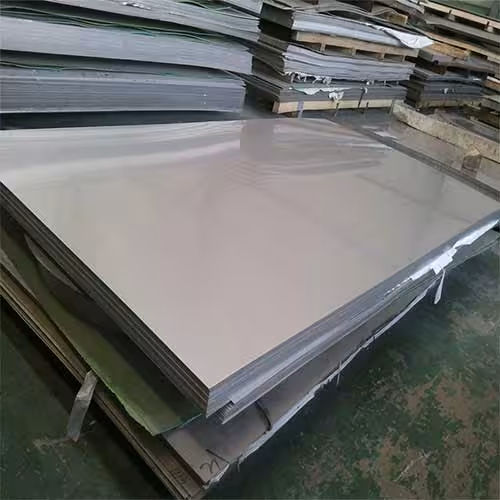

When it comes to choosing the right material for durability, hygiene, and especially corrosion resistance, few options compare to the 316 stainless steel plate. Whether you’re working in marine environments, food processing, or pharmaceutical manufacturing, this alloy offers exceptional performance where others fall short.

So, what exactly is 316 stainless steel? Read on to find out.

Understanding the Composition and Properties of 316 Stainless Steel Plate

The strength of 316 stainless steel plate lies in its composition. Compared to 304 stainless steel, the presence of 2-3% molybdenum makes 316 ideal for harsher environments. Here’s a breakdown of its typical chemical composition:

| Element | Percentage (%) |

|---|---|

| Chromium (Cr) | 16.0 – 18.0 |

| Nickel (Ni) | 10.0 – 14.0 |

| Molybdenum (Mo) | 2.0 – 3.0 |

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 2.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.045 max |

| Sulfur (S) | 0.03 max |

This specific composition results in:

- Outstanding corrosion resistance, particularly against chlorides

- Excellent weldability and formability

- High temperature strength and oxidation resistance

- Non-magnetic properties in the annealed condition

According to the International Stainless Steel Forum (ISSF), 316-grade stainless steel accounts for over 20% of all stainless steel production due to its superior properties in industrial and marine applications.

Key Applications of 316 Stainless Steel Plate Across Industries

The versatility of 316 stainless steel plate opens doors across a range of industries. Here are some practical, real-world scenarios where this alloy performs exceptionally:

Marine Environments

Saltwater environments can destroy standard metals, but 316 stainless steel plates are engineered to handle the harshest maritime conditions. They’re commonly used in boat fittings, seawater desalination plants, and dock hardware.

Food & Beverage Industry

With its non-reactive and easy-to-clean surface, 316 stainless steel plate is perfect for food processing equipment, brewing tanks, and commercial kitchen surfaces.

Pharmaceutical and Medical Equipment

Corrosion resistance and hygienic properties make it ideal for cleanroom tables, surgical tools, and medical trays. Its resistance to harsh sanitizing chemicals is a major plus.

Chemical Processing

316 stainless steel can withstand organic and inorganic chemicals, making it an excellent choice for storage tanks, piping systems, and pressure vessels.

Architecture and Construction

It’s often used in cladding, handrails, elevator panels, and outdoor structures where appearance and strength must be retained over time.

Here’s a quick application reference:

| Industry | Common Uses |

| Marine | Deck hardware, boat components |

| Food & Beverage | Storage tanks, food prep surfaces |

| Medical | Instrument trays, surgical tools |

| Chemical Processing | Piping, pressure vessels |

| Architecture | Cladding, handrails, façade panels |

How to Choose the Right 316 Stainless Steel Plate for Your Needs

When selecting a 316 stainless steel plate, consider these factors:

- Thickness: Standard gauges range from 3mm to over 25mm depending on structural demands.

- Surface Finish: For visual appeal and function, you can choose from #2B, #4, or mirror finishes.

- Temper: Annealed for formability or cold-rolled for strength?

- Certifications: Ensure compliance with industry standards like ASTM A240.

For custom fabrication or machining, always consult with a stainless steel supplier who understands your specific use case.

Maintenance Tips for Longevity of 316 Stainless Steel Plate

Although 316 stainless steel plates are highly corrosion-resistant, regular maintenance helps preserve both their appearance and performance. Here are some best practices:

- Routine Cleaning: Use warm water and mild detergent. Avoid abrasive pads.

- Passivation: Reapply a protective oxide layer if surface contaminants are present.

- Avoid Chloride Buildup: Even though 316 handles chlorides well, standing salt or chemicals should be rinsed away promptly.

Periodic inspection for signs of localized corrosion or pitting can extend the service life significantly, especially in aggressive environments.

Conclusion

From industrial machinery to aesthetic architecture, the 316 stainless steel plate is an investment in durability, hygiene, and corrosion resistance. Its chemical composition and physical properties make it one of the most reliable materials for critical environments.

Still wondering if it’s the right material for your project? Our team of stainless steel experts is here to help you evaluate specifications and provide tailored solutions. Contact us today to find the perfect 316 stainless steel plate for your needs.

FAQ

Is 316 stainless steel plate better than 304?

Yes, especially in corrosive environments. The added molybdenum gives 316 better resistance to chlorides.

Can 316 stainless steel rust?

While highly resistant, it can rust under extreme or neglected conditions. Regular maintenance prevents this.

Is 316 stainless steel magnetic?

No, it’s generally non-magnetic in its annealed form.

How much does 316 stainless steel plate cost?

Prices vary by thickness, finish, and market demand. For bulk or custom orders, contact us for a quote.

What finish options are available for 316 stainless steel plate?

Common finishes include #2B (matte), #4 (brushed), and BA (mirror polished).