Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Superior aluminum products are a cornerstone of modern European projects, from architectural facades in Paris to lightweight automotive components in Stuttgart. Renowned for their strength, corrosion resistance, and sustainability, these materials meet the region’s demand for durable, eco-friendly solutions. With Europe’s aluminum market valued at €80 billion and recycling rates exceeding 75%, as per European Aluminium, superior aluminum products align with stringent EU standards and innovative design needs.

This comprehensive guide explores why these products excel in construction, transportation, and manufacturing, offering a comparison table and FAQ to help architects, engineers, and project managers select the best aluminum solutions for sustainable, high-performance projects across Europe.

Exploring Superior Aluminum Products for Projects

Superior aluminum products encompass a range of alloys and forms, including sheets, extrusions, and castings, tailored for diverse applications. Their exceptional properties, driven by precise alloying, make them indispensable in Europe’s advanced industrial landscape. This section examines their composition, types, and project relevance, supported by insights from Aluminium Leader and European Aluminium, tailored to European professionals seeking reliable materials.

Composition of Superior Aluminum Products

The foundation of superior aluminum products lies in their alloyed composition, typically combining aluminum with elements like magnesium, silicon, or zinc. Common alloys, like 6061 (1% Mg, 0.6% Si), offer a tensile strength of 290 MPa, ideal for structural applications, as per Aluminium Leader. High-strength 7075 (5.6% Zn, 2.5% Mg) achieves 570 MPa, suited for aerospace, as noted by metallurgical data. A minimum 95% aluminum content ensures lightweight properties, with a density of 2.7 g/cm³, 65% lower than steel, as per European Aluminium. These compositions drive the performance of superior aluminum products, enabling robust, efficient project outcomes in European construction and manufacturing.

Types of Superior Aluminum Products

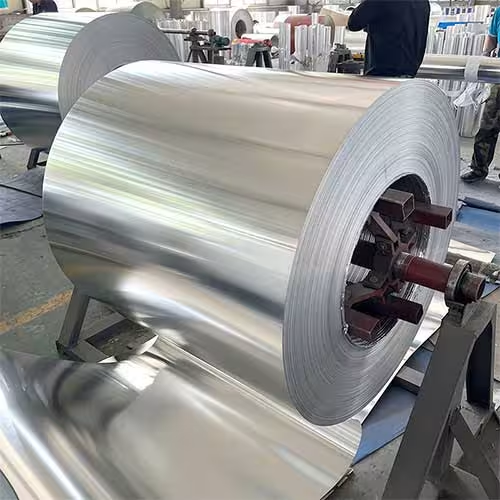

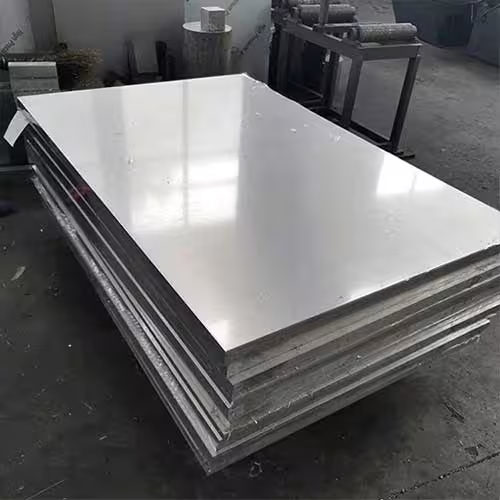

Superior aluminum products include sheets, plates, extrusions, and castings. Sheets, 0.2–6 mm thick, are used for cladding and roofing, offering corrosion resistance, as per industry standards. Extrusions, shaped into profiles, support window frames and automotive frames, with tolerances as low as ±0.1 mm, as noted by Aluminium Leader. Plates, over 6 mm thick, provide structural strength for bridges, while castings create complex components like engine parts, as per European Aluminium. Each type enhances the versatility of superior aluminum products, addressing Europe’s diverse project needs from architectural design to industrial manufacturing.

Applications of Superior Aluminum Products in Europe

Superior aluminum products are integral to European projects across multiple sectors. In construction, 6063 alloy extrusions form curtain walls in urban developments, resisting corrosion in humid climates like the Netherlands, as per Aluminium Leader. Automotive industries in Germany use 5083 alloy sheets for lightweight vehicle bodies, reducing fuel consumption by 10%, as noted by European Aluminium. Aerospace projects in France leverage 7075 alloy for airframe components, offering a strength-to-weight ratio 50% higher than steel, as per industry data. Packaging, like aluminum cans, benefits from 3004 alloy’s formability, supporting Europe’s recycling goals. These applications highlight why superior aluminum products are preferred for innovative, sustainable projects.

Advantages Driving Superior Aluminum Products

Superior aluminum products offer distinct advantages over alternatives like steel or plastic. Their lightweight nature, at 2.7 g/cm³, reduces structural loads by 30%, lowering transport emissions, as per European Aluminium. Corrosion resistance, due to a natural oxide layer, ensures a lifespan of 50+ years in coastal environments, unlike steel’s 10–20 years, as noted by Aluminium Leader. 100% recyclability, with 75% of European aluminum reused, aligns with EU’s Circular Economy Action Plan, as per industry reports. High thermal conductivity (200 W/m·K) suits heat exchangers, enhancing energy efficiency. These benefits make superior aluminum products a top choice for European projects prioritizing performance and sustainability.

European Context for Superior Aluminum Products

In Europe, superior aluminum products are shaped by stringent regulations and industrial innovation. The EU’s EN 573 standard ensures alloy quality, critical for construction and automotive applications, as per Aluminium Leader. The region’s 75% recycling rate, processing 12 million tonnes annually, supports sustainability, as noted by European Aluminium. Germany’s automotive sector, producing 3.7 million vehicles yearly, relies on aluminum for lightweighting, while Italy’s architectural projects use extrusions for aesthetic, durable designs, as per industry data. Compliance with REACH and RoHS regulations ensures safe, eco-friendly use, reinforcing why superior aluminum products are integral to Europe’s green and innovative project landscape.

Key Benefits of Superior Aluminum Products

The benefits of superior aluminum products—lightweight design, corrosion resistance, and sustainability—make them ideal for European projects. This section explores these advantages, providing technical insights for architects and engineers to optimize material selection, supported by industry data.

Lightweight Design in Superior Aluminum Products

The lightweight nature of superior aluminum products, with a density of 2.7 g/cm³, is a primary benefit. Compared to steel (7.8 g/cm³), aluminum reduces component weight by 65%, lowering fuel use in automotive applications by 10%, as per European Aluminium. In construction, lighter aluminum facades decrease foundation costs by 15%, as noted by Aluminium Leader. For aerospace, 7075 alloy’s high strength-to-weight ratio supports fuel-efficient aircraft, cutting emissions by 5%, as per industry studies. This lightweight design enhances the performance of superior aluminum products, making them essential for Europe’s energy-conscious projects in transportation and infrastructure.

Corrosion Resistance in Superior Aluminum Products

Corrosion resistance is a hallmark of superior aluminum products, driven by a self-healing oxide layer, 2–4 nm thick, that prevents rust, as per Aluminium Leader. Unlike steel, which corrodes in 1–5 years in coastal areas, aluminum withstands humid or saline environments for 50+ years, as noted by European Aluminium. Alloys like 5083, with 4.5% magnesium, excel in marine applications, such as ship hulls in Norway, as per industry data. This durability reduces maintenance by 40% compared to steel, ensuring superior aluminum products deliver long-term value for European projects in harsh climates.

Sustainability and Recyclability of Superior Aluminum Products

Sustainability is a key driver for choosing superior aluminum products. Aluminum is 100% recyclable, with 75% of Europe’s supply from recycled sources, reducing mining by 90%, as per European Aluminium. Recycling uses 5% of the energy required for primary production, cutting CO2 emissions by 95%, as noted by Aluminium Leader. The EU’s Circular Economy Action Plan, targeting 80% material recovery by 2030, favors aluminum’s closed-loop system, as per industry reports. Using superior aluminum products in projects like Swedish green buildings supports Europe’s net-zero goals, enhancing environmental and economic outcomes.

Versatility Across Alloys in Superior Aluminum Products

The versatility of superior aluminum products stems from diverse alloys tailored to project needs. Alloy 6061, with balanced strength and formability, suits structural beams, as per Aluminium Leader. Alloy 7075, with 570 MPa tensile strength, is ideal for aerospace components, as noted by European Aluminium. Alloy 3004, with high formability, supports can manufacturing, while 5083 excels in marine environments, as per industry data. This range ensures superior aluminum products meet Europe’s demands for precision, durability, and aesthetics in construction, automotive, and packaging projects, offering tailored solutions for diverse applications.

Aesthetic and Thermal Properties in Superior Aluminum Products

Superior aluminum products combine aesthetic appeal with excellent thermal performance. Anodized or powder-coated finishes provide sleek, durable surfaces for architectural facades, resisting fading for 20+ years, as per Aluminium Leader. Thermal conductivity of 200 W/m·K, 10 times higher than steel, makes aluminum ideal for heat exchangers in HVAC systems, improving efficiency by 15%, as noted by European Aluminium. Non-porous surfaces resist staining, requiring minimal cleaning, as per industry standards. These properties enhance the functionality and visual appeal of superior aluminum products, appealing to Europe’s design-conscious architects and engineers.

Comparison Table and Insights on Superior Aluminum Products

To illustrate why superior aluminum products are ideal, the following table compares common alloys, their properties, and project applications in Europe.

| Aluminum Alloy | Key Properties | Applications |

|---|---|---|

| 6061 | 290 MPa tensile, corrosion-resistant, formable | Structural beams, window frames |

| 7075 | 570 MPa tensile, high strength-to-weight | Aerospace components, automotive parts |

| 5083 | 4.5% Mg, saline-resistant, weldable | Marine hulls, vehicle bodies |

| 3004 | High formability, lightweight | Packaging cans, roofing sheets |

Insights on Superior Aluminum Products

The table highlights the adaptability of superior aluminum products. Alloy 6061’s balance of strength and formability suits construction projects, like bridges in Spain, as per Aluminium Leader. Alloy 7075’s high strength supports aerospace in France, reducing aircraft weight by 20%, as noted by European Aluminium. Alloy 5083’s saline resistance is ideal for marine applications in Norway, while 3004’s formability drives packaging in Italy, as per industry data. Selecting the right alloy ensures superior aluminum products meet project-specific demands, aligning with Europe’s quality and sustainability standards across diverse sectors.

Strategies for Selecting Superior Aluminum Products

To choose superior aluminum products, assess project requirements and environmental conditions. For construction, select 6061 or 6063 for corrosion-resistant extrusions, as per Aluminium Leader. Aerospace projects require 7075 for high strength, verified by EN 755 standards, as noted by European Aluminium. Marine applications benefit from 5083, tested for saline exposure, as per industry guidelines. Verify recycled content (70%+) to meet EU sustainability goals, and consult suppliers for alloy certifications, as per technical data. These strategies ensure superior aluminum products deliver performance and compliance in European projects, from urban infrastructure to industrial manufacturing.

Practical Considerations for Superior Aluminum Products

Effective use of superior aluminum products involves strategic selection, integration, and maintenance. This section provides actionable guidance for European professionals to maximize performance and sustainability.

Selecting Superior Aluminum Products for Projects

Choosing superior aluminum products starts with defining project goals. For architectural facades in Denmark, 6063 extrusions with anodized finishes ensure aesthetic durability, as per Aluminium Leader. Automotive projects in Germany should use 5083 sheets for lightweight, corrosion-resistant bodies, as noted by European Aluminium. Aerospace applications in the UK require 7075 plates, certified to EN 485, as per industry standards. Verify alloy purity and recycled content via EN 573 compliance, and request samples to test performance, ensuring superior aluminum products meet Europe’s rigorous quality and environmental requirements for construction, transportation, or packaging.

Integrating Superior Aluminum Products in Projects

Integration of superior aluminum products demands precision and compatibility. Use CNC machining for 6061 extrusions to achieve ±0.1 mm tolerances in structural frames, as per Aluminium Leader. In automotive assembly, weld 5083 sheets using MIG techniques to maintain strength, as noted by European Aluminium. For aerospace, bolt 7075 components with titanium fasteners to prevent galvanic corrosion, as per industry guidelines. Incorporate thermal breaks in construction to enhance insulation, reducing energy use by 10%, as per technical data. Proper integration ensures superior aluminum products deliver structural integrity and efficiency in European projects, from buildings to vehicles.

Maintaining Superior Aluminum Products

Maintenance preserves the performance of superior aluminum products. Clean anodized surfaces with mild soap and water, avoiding abrasives to prevent scratches, as per Aluminium Leader. Inspect welds on 5083 marine components quarterly for pitting, especially in saline environments, as noted by European Aluminium. Apply protective coatings, like powder coating, to 6063 extrusions every 5–10 years to extend lifespan, as per industry standards. Regular maintenance reduces repair costs by 30% and ensures compliance with EU’s EN 15088 for structural aluminum, as per technical reports, keeping superior aluminum products pristine in European applications.

Sustainability Practices with Superior Aluminum Products

Sustainability enhances the appeal of superior aluminum products. Specify alloys with 70–80% recycled content to reduce emissions by 90%, as per European Aluminium. Partner with suppliers offering take-back programs for end-of-life aluminum, supporting EU’s 80% recovery target by 2030, as noted by Aluminium Leader. Use low-energy fabrication, like cold forming, to cut production emissions by 15%, as per industry data. In construction, design modular aluminum systems for disassembly, enabling reuse, as per EU Circular Economy guidelines. These practices ensure superior aluminum products contribute to Europe’s net-zero ambitions in architecture and manufacturing.

Challenges in Using Superior Aluminum Products

Challenges in adopting superior aluminum products include galvanic corrosion, cost misconceptions, and fabrication complexity. Contact with dissimilar metals, like steel, can cause corrosion, mitigated by insulating coatings, as per Aluminium Leader. Some assume aluminum is costlier than steel, but its 50-year lifespan and recyclability offset initial costs, as noted by European Aluminium. Complex extrusions require skilled machining, increasing lead times, as per industry data. Address these by selecting compatible alloys, verifying lifecycle benefits, and training fabricators, ensuring superior aluminum products deliver value in European projects without compromising performance or sustainability.

Conclusion

Superior aluminum products offer unmatched lightweight design, corrosion resistance, and sustainability, making them ideal for European construction, automotive, aerospace, and packaging projects. By selecting the right alloys, integrating them effectively, and prioritizing maintenance, professionals can maximize performance and compliance.

This guide, with its table and FAQ, equips readers to harness these materials for innovative, eco-friendly outcomes.

FAQ

What are superior aluminum products?

They are high-quality aluminum alloys, like 6061 or 7075, used in construction, automotive, and aerospace for durability.

Why choose superior aluminum products for projects?

Their lightweight, corrosion-resistant, and recyclable properties reduce emissions and costs by 10–90%, as per industry data.

What alloys are used in superior aluminum products?

6061, 7075, 5083, and 3004, tailored for structural, aerospace, marine, and packaging applications.

How do superior aluminum products resist corrosion?

A self-healing oxide layer prevents rust, ensuring 50+ years of durability in harsh environments.

What are the applications of superior aluminum products?

Construction facades, vehicle bodies, aircraft components, and packaging cans, supporting Europe’s industries.